Slated for completion in Q2 of 2024, Geneo

features a 27m-tall mass timber canopy

containing 1,145 m3 of structural glulam,

storing 952 tonnes of CO2-e

A 2 hr fire rated Canopy sprawling over 3100m2

Innovation includes Girod connections full

assembly tested in Singapore.

Current LCA calculations put GHG emissions for the entire value chain at around 70 tCO2e, which results in the timber

structure being carbon negative – a carbon storage value of over 950 tonnes of CO2-e.

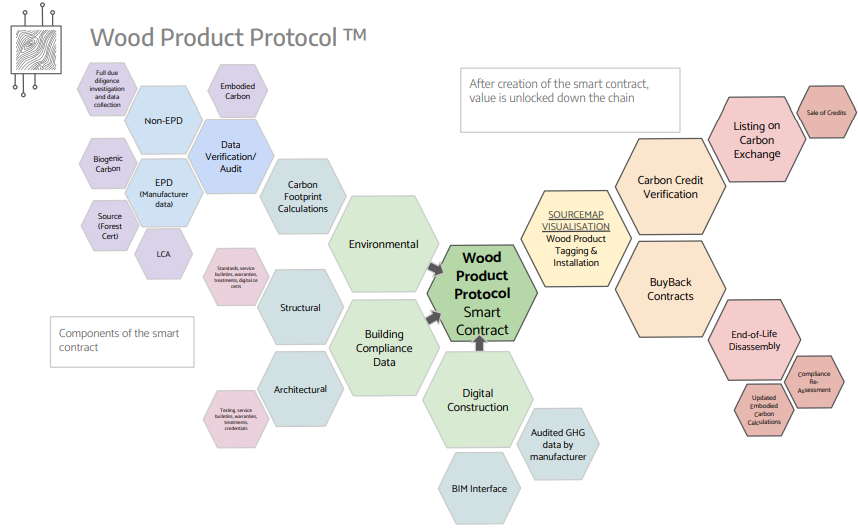

GHG data, with manufacturing, certification and compliance data, was tokenised on a Web3 format

Forming the building blocks for onward use in emissions reporting or converted into carbon storage credits . Setting up the

material for future BuyBack programs.